|

Ball Valve American made ball valves by Valtorc International. American made, great pricing items in stock ready to ship.

|

|

PCB Surface Processes |

|

|

|

|

| |

Provides a solderable surface for Component assembly. Provides a solderable surface for Component assembly.

Protect Copper Surface from Oxidation. Protect Copper Surface from Oxidation.

Provide a surface appropriate for wear related parts. Provide a surface appropriate for wear related parts.

Mixed Technology Board Designs Mixed Technology Board Designs

Solderable,SMT and Thru-hole Solderable,SMT and Thru-hole

Wire Bondable Wire Bondable

Contact Resistance Contact Resistance

Co-Planar Surfaces Co-Planar Surfaces

Compatability with variety of fluxes & paste Compatability with variety of fluxes & paste

Cost effective Cost effective

Environment Environment

Electroless Nickle-Immersion Gold Electroless Nickle-Immersion Gold

Immersion Silver Immersion Silver

Hot Air Solder Level Hot Air Solder Level

Organic Solderability Preservative Organic Solderability Preservative

Electrolyte Nickel - Hard Gold Electrolyte Nickel - Hard Gold

Electrolyte Nickel - Soft Gold Electrolyte Nickel - Soft Gold

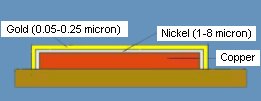

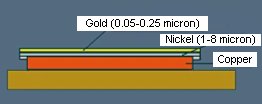

Electroless Nickel-Immersion Gold (ENIG) Electroless Nickel-Immersion Gold (ENIG)

A two layer, gold over nickel, metallic surface finish plated onto the copper base by means of a chemical decomposition process. A two layer, gold over nickel, metallic surface finish plated onto the copper base by means of a chemical decomposition process.

| Advantage |

Disadvantage |

- Typical Thickness: 3-8 uin gold over 150-250 uin nickel

- Excellent Corrosion resistance

- Good for aluminium wire bonding

- Excellent flatness for fine-pitch technology

- Excellent Solderability

- Excellent shelf life(12 mo)

- Good surface contrast

- Good contact resistance

- High Aspect Ratio Capability

|

- Narrow process window

- Higher cost than HASL(1.5 to 2.0 times)

- Back pads: brittle solder joints

- Fatigue failures on large BGA packages

- Skip plate

- Extraneous nickel plating

- Solder mask capability with the nickel bath

|

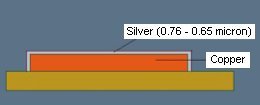

A co-deposit of silver and organics A co-deposit of silver and organics

| Advantage |

Disadvantage |

- Typical coating thickness: 5-25 uin

- Very good alternative to HASL (lead free)

- Similar cost to HASL

- Excellent Solderability,(Comparable to Solder)

- Excellent for fine pitch and BGA's technologies

- Holes Capability over 10:1 aspect ratio

- Press fit connector's capability

- Mulitple heat cycles during assembly process

- Reworkable product(at fabricator)

- Selective gold compatible

- Good Shelf life ,6 months to 12 months

- Conductive during PCB testing

- Low % Silver dissolved into silver joint

|

- No thermal cycle after Immersion

- Silver at the Fabricator

- Vias cap:UV curable only

- Handling

- Some resistance from the OEM to use

- Immersion Ag with press fit connectors

- Micro-void in the solder joints

- Also found on other surface finishes

- Discoloration due to reaction with sulfur in the air.

- (Does not impact solderability)

|

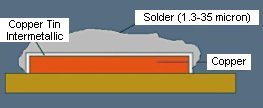

A molter solder immersion and hot air leveling(blasting) of surfaces and holes to provide a "pretinned" coating on exposed copper surfaces. A molter solder immersion and hot air leveling(blasting) of surfaces and holes to provide a "pretinned" coating on exposed copper surfaces.

| Advantage |

Disadvantage |

- Typical coating thickness specifications

- 100-1000 uin with average of 150-300 uin fine pitch

- 40-1000 uin on discrete pads with average 80 uin

- coverage on large surface (ground plane) 15-40 uin

- Excellent solder "Nothing solders better than solder"

- 20mils pitch capability; dependent on technology

- Board thickness up to 200 mils

- Panel size up to 24 x 28 inches

- One of the less expensive surface finish

- Good shelf life

|

- Uniformity of the coating

- Thermal shock

- Limited capability on high density borads

- Limited capacity to clear vias holes

(>6:1 aspect ratio)

- Difficulty to maintain hole size tolerance along

plated edges

- Difficulty to process thin material

- Require a different drill selection.

(Press fit connector dictate the drill)

- Process very dependant of the board technology

- Intermetallic layer grows with time and heat cycle

- Use of Lead

|

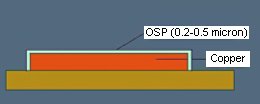

A water based Organic compound that selectively bonds with copper to provide an organomettalic layer that protects the copper for soldering A water based Organic compound that selectively bonds with copper to provide an organomettalic layer that protects the copper for soldering

| Advantage |

Disadvantage |

- Typical coating thickness: 8-20 uin

- Major advantage: Gold doesn't need to be protected

- The least expensive surface finish

- Reworkable

- Shelf life (6 months)

- New lead free OSP formulations available

|

- Difficult or impossible to inspect the final product

- Skip Plating

- Residue on Copper

- Coating thickness

- Difficult to soldermask via cap

- Electrical testing prior to coating

- Micro-void in the solder joints

- also found on other surface finishes

- Solder may not wet to corners of large SMT pads

(still good solder joint)

|

A two layer,gold over nickel,metallic surface finish plated onto the copper base by means of a electrolytic deposition process. A two layer,gold over nickel,metallic surface finish plated onto the copper base by means of a electrolytic deposition process.

| Advantage |

Disadvantage |

- Good Connector. Typical thickness 30-50 uin

minimum gold (99.7 %)

over 150 uin minimum nickel

- Solderable Surface. Typical thickness 5-15 uin

minimum gold (99.7 %)

over 150 uin minimum nickel

- Excellent corrosion resistance

- 130 to 200 Knoop hardness

- Excellent wear resistance for surface rotary switches, on-off contacts,and edge connectors

- Excellent shell life

|

- Gold Distribution

- Throwing power in the holes

- The copper is exposed on the sides of the traces

- Porosity

- Difficulty to measure the true line width

- Soldermask adhesion on gold

|

| Advantage |

Disadvantage |

- Good Connector. Typical thickness 30-50 uin

minimum gold (99.7 %)

over 150 uin minimum nickel

- Solderable Surface. Typical thickness 5-15 uin

minimum gold (99.7 %)

over 150 uin minimum nickel

- Excellent corrosion resistance

- 130 to 200 Knoop hardness

- Excellent wear resistance for surface rotary switches, on-off contacts,and edge connectors

- Excellent shell life

|

- Gold Distribution

- Throwing power in the holes

- The copper is exposed on the sides of the traces

- Porosity

- Difficulty to measure the true line width

- Soldermask adhesion on gold

|

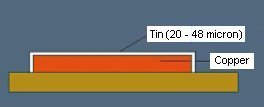

A co-deposit of Tin and organics A co-deposit of Tin and organics

| Advantage |

Disadvantage |

- Back Plane

- Press fit connectors Technology

- Reworkable

- Reworkable

|

- Soldermask compatability

- Thiourea (TU)

- High temperature of the Tin bath

- Process control:Solderability Test (Tin porosity)

- Intermetallic growth

- Solderabilty goes down significantly with each reflow cycle

- Unable to analyze chemistry directly

- solderabilty test(6-8 hr test)

|

Lead Free Compatible OSP Lead Free Compatible OSP

Enthone 106 HT Designed for Lead Free re-flow Profiles

Drop in Alternative to 106 AX (for Merix and CMS)

Survive Extra re-flow Cycle in a tin/lead Assembly

Easy Control Process

UIC Immersion Silver UIC Immersion Silver

Investigating to Reduce or Eliminate Tarnishing

Testing Planned

|

|

|

|

|

|